Live metrics with an optical measurement system: What to expect

Live metrics with an optical measurement system: What to expect

Blog Article

Checking out the Applications of Optical Measurement Solutions in Different Industries

You might not understand exactly how important optical measurement systems are throughout different markets. They enhance accuracy in manufacturing, improve diagnostics in health care, and assurance safety and security in aerospace. These systems are reinventing exactly how you view top quality and performance. What does the future hold for these modern technologies? Exploring their applications discloses not just existing advantages however also interesting possible developments on the horizon.

Optical Measurement Equipments in Manufacturing

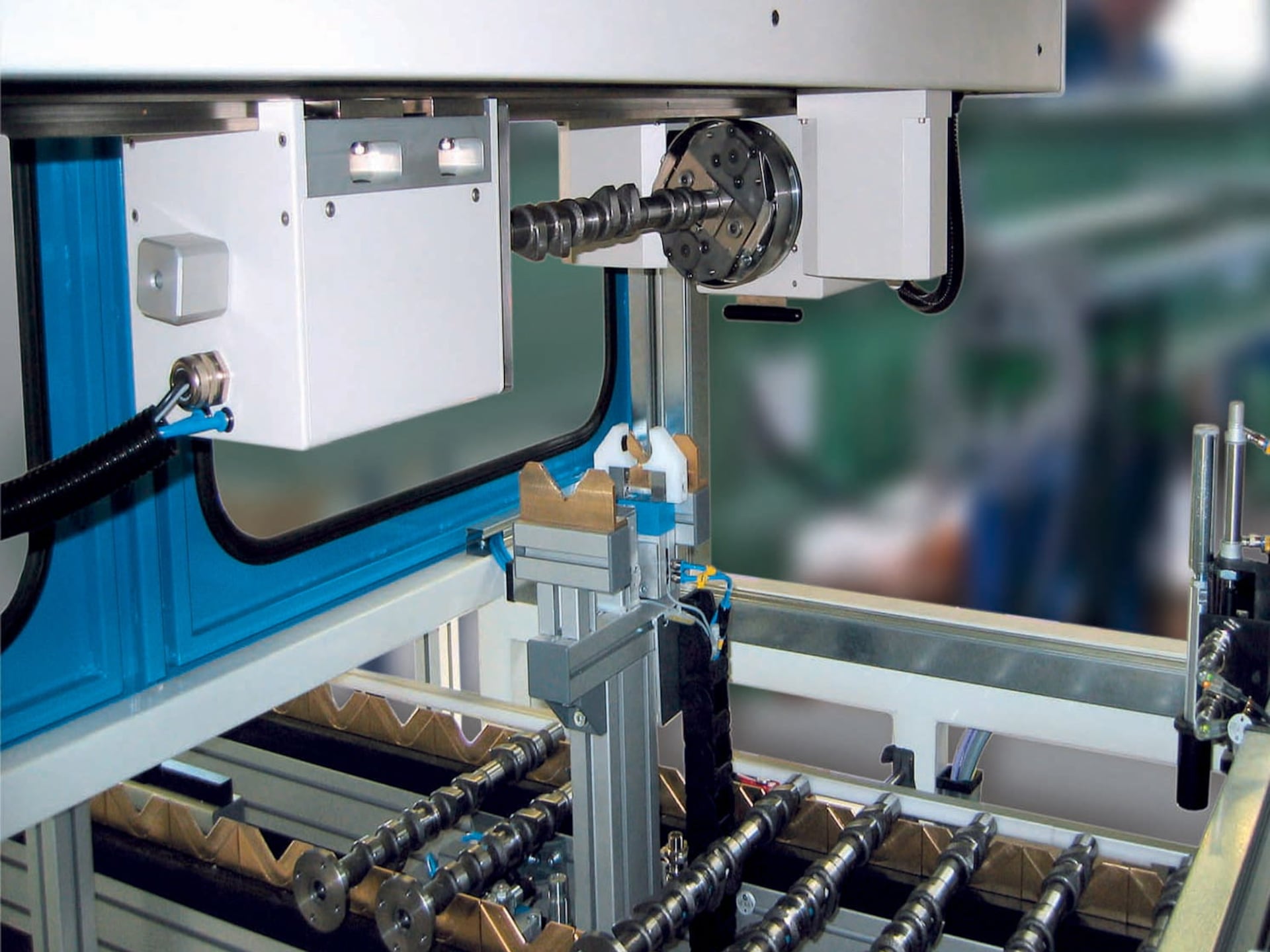

As producing procedures become significantly intricate, optical dimension systems play an important function in assuring accuracy and effectiveness. You count on these systems to improve quality control, enhance production, and lower waste. By utilizing advanced imaging methods, you can precisely gauge dimensions, surface profiles, and also worldly homes in real-time.

These systems assist you recognize flaws early in the manufacturing process, enabling for fast modifications and minimizing pricey errors. Whether you remain in auto, aerospace, or electronics, optical measurement systems adjust to your particular demands, enhancing your workflow and performance.

Furthermore, their non-contact nature assurances that fragile elements stay unharmed throughout inspection. Applying these innovations not just improves your operational capabilities but likewise boosts the general quality of your products. In an industry where accuracy is vital, optical measurement systems give the benefit you require to stay affordable and fulfill demanding criteria.

Enhancing Medical Care Diagnostics With Optical Technologies

Optical modern technologies are transforming healthcare diagnostics, similar to they've transformed producing procedures. You can see exactly how these developments enable much faster, a lot more exact condition detection and tracking. For circumstances, optical comprehensibility tomography (OCT) offers high-resolution pictures of the retina, permitting early detection of conditions like glaucoma and diabetic retinopathy.

Furthermore, fluorescence microscopy can help you determine details cellular markers, improving cancer diagnostics. With non-invasive strategies like optical spectroscopy, you're able to examine cells properties, providing real-time understandings without the need for biopsies.

These innovations not just boost patient end results but additionally streamline operations in scientific settings. By integrating optical measurement systems into diagnostics, you're guaranteeing an extra reliable technique to healthcare. As these modern technologies proceed to evolve, you can anticipate also better developments in accuracy medication, causing tailored treatments that satisfy specific client requirements.

The Duty of Optical Measurement in Automotive Industries

In the automobile industry, accuracy in element production is important for safety and security and performance. You'll find that optical measurement technologies play a necessary duty in making certain high quality control and guarantee throughout the production procedure. By integrating these systems, suppliers can boost precision and reduce mistakes, inevitably resulting in better cars.

Accuracy in Element Production

You count on optical measurement systems to assure every element fulfills strict requirements. By integrating optical dimensions right into your manufacturing processes, you can minimize and decrease mistakes waste, eventually saving time and cash. With optical dimension, you improve the dependability of your parts, ensuring they execute at their finest in the requiring auto environment.

Quality Assurance and Assurance

Quality assurance is an essential element of auto manufacturing, guaranteeing that every component satisfies stringent safety and security and performance criteria. By incorporating optical dimension systems, you can improve your top quality assurance procedures substantially. These systems supply exact, non-contact dimensions that help spot flaws and variations in elements quickly. With real-time data, you can make educated choices, decreasing the danger of defective components reaching the setting up line. Optical dimension additionally helps in validating dimensions and surface area qualities, guaranteeing they align with specifications. And also, the automation of these processes lessens human mistake, raising overall performance. Inevitably, using optical dimension systems not just boosts item top quality yet also reinforces your brand's reputation in an affordable market.

Optical Systems in Aerospace and Protection Applications

In aerospace and defense, optical systems play an essential function in ensuring security and effectiveness. You'll find precision measurement strategies and structural integrity analyses essential for keeping airplane and military devices. And also, real-time monitoring systems improve situational understanding, making them crucial in today's protection strategies.

Accuracy Measurement Strategies

While numerous markets count on numerous dimension techniques, the aerospace and defense markets require extremely high criteria for precision and reliability. In these areas, precision measurement strategies utilizing optical systems play an essential function. You'll locate that laser-based systems, as an example, allow you to evaluate ranges and measurements with exceptional precision, essential for part positioning and setting up. Additionally, interferometry assists in detecting min surface abnormalities, ensuring that every part fulfills rigorous specs. These optical methods not only improve measurement precision however also enhance effectiveness by minimizing the time required for analyses. By leveraging these advanced methods, you can significantly strengthen the stability and efficiency of aerospace and protection applications, ultimately boosting safety and security and functional performance.

Structural Integrity Evaluation

As you analyze structural honesty in aerospace and protection applications, optical dimension systems confirm important. These systems use specific, non-contact approaches for examining the condition of critical components, making sure safety and reliability. By making use of techniques like laser scanning and interferometry, you can detect minute contortions and stress concentrations that could compromise architectural honesty. This real-time data helps you make informed choices regarding repair and maintenance, inevitably expanding the life expectancy of airplane and army devices. Additionally, the capacity to visualize information in 3 dimensions enhances your understanding of prospective failing factors. By integrating these optical systems into your assessment methods, you're not only improving accuracy yet likewise improving general operational effectiveness sought after aerospace and protection environments.

Real-Time Security Equipments

Building on the reference relevance of optical dimension systems for architectural stability, real-time security systems play a pivotal function in enhancing situational awareness in aerospace and defense applications. These systems use innovative optical technologies, consisting of high-resolution cams and LiDAR, to keep an eye on environments continuously. You can track potential dangers, examine mission-critical procedures, and warranty safety by incorporating these systems right into aircraft and ground cars. Real-time information analysis enables fast decision-making, adapting to swiftly changing scenarios. Optical surveillance aids in reconnaissance objectives, supplying in-depth images and understandings without jeopardizing safety and security. By welcoming these innovations, you're not just boosting operational performance but additionally strengthening protection capabilities in an ever-evolving landscape.

Innovations in Optical Measurement for Environmental Monitoring

Optical dimension modern technologies have actually substantially evolved, improving our ability to keep track of environmental modifications with unmatched accuracy. You can currently utilize advanced sensing units that utilize light to discover air high quality, water purity, and even biodiversity. These systems supply real-time data, allowing you to react quickly to environmental dangers.

As an example, remote sensing techniques allow the analysis of deforestation and urban spread, using satellite imagery to track modifications in time. Spectroscopy approaches have actually improved your capacity to recognize pollutants at minute focus, ensuring conformity with environmental guidelines.

Additionally, improvements in LiDAR innovation allow for accurate topographic mapping, essential for flood risk management and habitat conservation. By integrating these optical measurement systems into your ecological monitoring methods, you'll acquire valuable understandings that drive informed decision-making and promote sustainability. Embracing these technologies can equip you to secure our planet much more efficiently than ever.

Optical Measurement Solutions in Electronic Devices and Semiconductor Industries

In the fast-paced globe of electronics and semiconductors, leveraging sophisticated optical dimension services can markedly improve making processes and item high quality. These systems allow you to assess critical specifications such as thickness, surface roughness, and function sizes with extraordinary precision. By utilizing methods like laser triangulation and interferometry, you can discover minute issues that typical approaches could miss out on.

Executing optical measurement solutions helps enhance production lines, guaranteeing that your items fulfill strict high quality requirements (optical measurement system). You'll find that real-time information collection facilitates fast modifications, minimizing waste and lessening rework. Additionally, these systems can be incorporated right into automated workflows, improving overall effectiveness

As you embrace optical dimension technologies, you'll enhance your one-upmanship in a quickly advancing market. The accuracy and reliability these options supply not only improve product performance however likewise bolster your online reputation for top quality, making them vital in the electronic devices and semiconductor industries.

Future Patterns and Innovations in Optical Measurement Systems

As markets proceed to welcome sophisticated technologies, the future of optical dimension systems looks appealing. You'll see improvements in man-made intelligence and artificial intelligence boosting information evaluation, enabling quicker and a lot more precise dimensions. Real-time tracking will certainly become typical, enabling instant modifications in making procedures.

Miniaturization of sensing units will additionally play a crucial role, making optical systems more obtainable and portable for numerous applications. Anticipate technologies in 3D imaging and holography to change quality control, supplying deeper insights into item honesty.

Sustainability will drive the advancement of environment-friendly optical measurement remedies, lowering waste and energy consumption. In addition, combination with the Web of Points (IoT) will assist in seamless data exchange, leading the way for clever manufacturing.

Frequently Asked Inquiries

What Are the Key Parts of Optical Measurement Systems?

The key elements of optical measurement systems consist of light sources, filters, detectors, and lenses. You'll locate that these aspects collaborate to catch and analyze data accurately, ensuring exact dimensions in numerous applications.

Exactly How Do Optical Measurement Systems Compare to Conventional Measurement Techniques?

Optical dimension systems offer better accuracy and speed compared to typical methods. You'll notice they decrease human mistake, offer non-contact alternatives, and assist in complicated dimensions, making them a smarter choice for exact information collection.

What Industries Are Becoming Customers of Optical Dimension Technologies?

You'll locate emerging sectors like aerospace, automotive, and medical care progressively adopting optical measurement technologies. These sectors take advantage of enhanced accuracy and effectiveness, driving development and improving high quality in their processes and products. It's quite exciting!

What Are the Price Implications of Executing Optical Dimension Solutions?

Carrying out optical dimension systems can be pricey upfront, but you'll often see long-term cost savings from enhanced accuracy and efficiency. You'll likewise reduce waste and enhance item high quality, leading to far better client complete satisfaction and greater revenues.

Just How Can Business Make Sure Accuracy and Dependability in Optical Measurements?

To guarantee accuracy and dependability in optical measurements, you should frequently calibrate your equipment, train drivers thoroughly, maintain a controlled environment, and make use of high-quality elements. These actions reduce errors and improve dimension uniformity.

Conclusion

Inevitably, optical measurement systems official website are changing several industries by enhancing accuracy and efficiency. Accepting optical dimension systems now can set you apart in today's affordable landscape.

As making procedures end up being significantly complicated, optical dimension systems play an essential duty in ensuring precision and efficiency. By including optical dimension systems, you can improve your high quality guarantee procedures considerably. Inevitably, utilizing optical dimension systems not only enhances item top quality yet also enhances your brand's track record in a competitive market.

Structure on the relevance of optical dimension systems for architectural stability, real-time monitoring systems play a pivotal function in improving situational recognition in aerospace and defense applications - optical measurement system. How Do Optical Dimension Systems Compare to Traditional Measurement Techniques?

Report this page